- 03 9354 4717

- This email address is being protected from spambots. You need JavaScript enabled to view it.

- Mon - Fri 9:00:- 5:00 Sat 10:00 - 2:00

Crossflow Ventilation Requirements & Assessment

Understanding crossflow ventilation and BCA and VBR requirements.

- Most dwellings constructed over joist and bearers are 'bricked in or cladded in' from finished floor height down and lack sufficient crossflow ventilation, ventilation that is crucial to the performance of structural timber products including timber flooring.

- When a sub-floors space is not correctly ventilated the result will be an increase in humidity levels in the sub-floor space. Allowing timber products to uptake moisture. Expansion, swelling, tenting, cupping, changes to nominal manufactured size of construction material will become evident has a result of poor crossflow ventilation.

- Bushy surroundings, dense gardens, geographic location and elevation may also cause higher humidity to the sub-floor space, crossflow ventilation efficiency should be carefully designed to ensure the correct crossflow ventilation to prevent mould build up on walls, ceilings, distinct musty smell inside the dwelling and moisture uptake into structural framing and timber flooring.

Building Code of Australia (BCA).

- The BCA levels (currently limited to 6000 mm² per metre length of wall for higher humidity areas) are primarily to limit the moisture content of sub-floor framing timbers, which can generally tolerate greater fluctuations in moisture content, than timber floors. The recommended minimum ventilation for timber floors is 7500 mm2 per metre length of wall, with vents evenly spaced to ensure that cross ventilation is provided to all the sub-floor area.

- In some localities, to meet constraints associated with energy efficiency, it may be decided to reduce ventilation levels to the values provided in the BCA.

- The BCA also outlines that a moisture barrier over the soil beneath the building reduces ventilation requirements and this approach is equally applicable to timber floors. If ventilation is below the recommended level, due consideration should be given to alternative measures as outlined above.

- Particular attention should be paid to ensuring that the subfloor space remains dry throughout all seasons.

- The type of vent may also need to be considered as in bushfire areas the mesh size used in vents is limited. Some commercially available vents of various types, their dimensions, net ventilation area and required spacing for coastal Zone 3 is provided below. BCA relative humidity zones and associated BCA ventilation requirements are also provided below.

- The maximum vent spacing irrespective of net ventilation area is 2 m and any screens that may be necessary in bushfire areas or for vermin proofing may restrict airflow and this may need to be compensated for.

- The sub-floor space must be free from all building debris and vegetation.

- Obstacles that prevent airflow to and from vents will reduce the efficiency of the sub-floor ventilation system.

- Landscaping around the external perimeter of the sub-floor space and structural elements should not limit airflow.

- Vents should be installed in the masonry course below floor bearers, and should not be obscured by engaged piers or piers/stumps/columns, or by any services.

- Where external structures (fences, etc) or landscape may reduce airflow, consideration should be given to the use of more than the minimum number of vents.

- Where verandah's or decks are constructed outside the dwelling perimeter, care should be taken to ensure that the amount of ventilation provided around the verandah or deck perimeter is equivalent to or greater than the amount required for the adjacent external wall.

- Where ventilation is obstructed by patios, etc, additional ventilation should be provided to ensure that the overall level of ventilation is maintained and crossflow is achieved.

- If adequate natural ventilation cannot be provided to sub-floor spaces, a mechanical ventilation system should be installed which replaces all the air in this space on a regular basis and prevents the formation of 'dead-air spaces'.

- If there are doubts over the sub-floor humidity(areas of high water table, reduced airflow due to minimum clearances between the sub-floor framing and ground, external structures, etc) again a polyethylene membrane laid over the soil should be considered (taped at joints and fixed to stumps and walls). As discussed above, this can significantly reduce moisture uptake by the sub-floor air. Increased levels of ventilation should also be considered in such instances.

- With dwellings on sloping blocks that have enclosed sub-floor spaces, the possibility of seepage should be taken into consideration and appropriate control measures taken prior to the installation of the floor.

- The drainage system provided to the dwelling site, should ensure that run-off water will drain away from the building perimeter (not towards it) and that run-off water is prevented from entering the sub-floor space.

- The ground beneath a suspended floor should also be graded so that no ponding is possible.

- Where springs or aquifers are present (e.g. exposed by earthworks on sloping sites) and cause water to enter the sub-floor space, a closed drainage system should be installed under the dwelling to remove this water. The ventilation system will not cope with this level of moisture in the subfloor space.

Important information for timber flooring:

Sub-floor cross ventilation should exceed the minimum BCA requirements when any form of timber flooring is installed to ensure its performance the requirement is 7500 mm2 per metre length of wall.

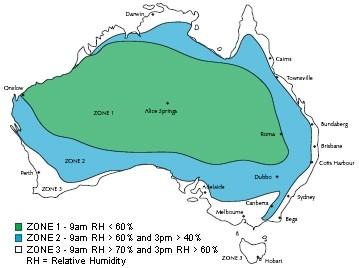

The amount of ventilation depends on the location of the site in Australia. This is governed by relative humidity; the relevant zone can be read off Map 1. Using Table 1, select the appropriate climate zone and read off the required ventilation area per metre of subfloor wall. Amounts vary depending on whether a sealed impervious ground membrane is used or not.

Table 1 (Source: BCA 2007)Minimum sub-floor ventilation (mm2/m of wall)

Climate Zone No impervious membrane over sub-floor ground Sub-floor ground sealed with impervious membrane

1 2000 1000

2 4000 2000

3 6000 3000

The sealed ground membrane option assists where special consideration is required for sub-floor ground which is subject to excessive dampness or frequent flooding. Care must also be taken to ensure patios, paving and similar construction does not limit the effectiveness of ventilation. Further details are in the BCA.

Map 1: Climatic zones based on relative humidity (Source: BCA 2007)

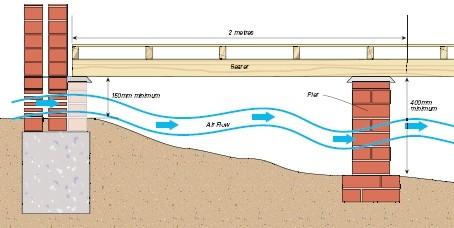

Fig 9: Minimum underfloor clearance - Refer to AS3660.1

Unless full underfloor physical or chemical barriers are provided, sub-floor clearance must be provided to enable regular inspection.

Where required, sub-floor clearance must be a minimum of 400 mm to the underside of bearer, except on sloping sites where part of the area may be a minimum of 150 mm clearance as shown in Fig. 9.

The amount of ventilation depends on the location of the site in Australia. This is governed by relative humidity; the relevant zone can be read off Map 1. Using Table 1, select the appropriate climate zone and read off the required ventilation area per metre of subfloor wall. Amounts vary depending on whether a sealed impervious ground membrane is used or not.

How to calculate the number of vents needed in a wall:

- Say you're inspecting the subfloor area of a building in climate zone 3, and you're looking at a wall that is 8 metres long. The building uses old-fashioned terracotta vents with an opening size of 3,840 mm2.

- How many vents should there be in the wall?

Step 1. Find out what the total ventilation area should be in the wall

In climate zone 3, the minimum requirement is 6,000 mm2 per metre of wall.

This wall is 8 metres long. Therefore, the minimum requirement is:

8 (metres) x 6,000 (mm2) = 48,000 mm2 - Step 2. Divide the total area by the area of one vent

48,000 mm2 ÷ 3,840 mm2 = 13 vents (rounded up to the nearest whole number).

Further BCA requirements

- Under AS 3660, the minimum clearance allowed is 400 mm, except for the last 2 metres around the perimeter, where it can slope up to 150 mm minimum clearance.

- The general Australian Standard requirement for the spacing of air vents is that they should be placed within 600 mm of corners and be spaced evenly around the perimeter walls of the building tp prevent dead air pockets.

- Unfortunately, sub-floor ventilation is often a forgotten part of termite management. The BCA (Vol. 2) requires the sub-floor between a suspended floor and the ground to be ventilated. This minimises sub-floor moisture which helps to prevent timber decay, and creates an environment that discourages termite attack.

- Important building practices:

- Sub-floor space should be free of building debris and vegetation.Sub-floor space should have effective crossflow ventilation.

- Sub-floor space should not contain any dead air spaces.Sub-floor space natural ground level requires to be above the final external ground level inclusive of external paving.

- Sub floor space should be evenly graded to prevent ponding and achieve effective water runoff.

- Vents should be evenly spaced.

- Vents should be place within 600mm of corners to eliminate dead air spaces.

- Vents size and spacing should be calculated correctly per length of wall.

- Vents must be below bearer level to ensure maximum efficiency.

- Vents should not be blocked by any form of appliances or services.

- External paving or natural ground level should be graded away from sub-floor spaces.

- Flower beds or boxes should not minimize the efficiency of crossflow ventilation requirements.

- Special care should be taken with garden irrigation to prevent excessive moisture to enter the sub-floor space.

- Decking's, verandahs and patios should not limit crossflow ventilation to sub-floor space if ventilation is effected steps should be taken to achieve the correct BCA requirements.

- If crossflow ventilation requirements cannot be met due to site conditions mechanical ventilation systems should be designed and implemented to meet the BCA requirements.

Important notes for building of extensions to exiting dwellings:

In many cases crossflow ventilation is overlooked in the design and construction of extensions to existing dwellings.

- When extension are added to an existing home where the original home is built over joist and bearers and the extension is built over concrete slab care should be taken to ensure correct sub-floor ventilation is achieve to the joist and bearer construction.

In most investigated sites crossflow ventilation, has been non-compliant causing humidity levels to rise. Site drainage was also found to be ineffective and non-compliant resulting in damage to both structural components and timber flooring. In most cases, mechanical ventilation had to be introduced to achieve the correct crossflow ventilation and site drainage had to be improved.

- Site drainage must be considered carefully to stop water ponding this is particularly crucial to sloping sites where the new concrete slab could potentially act as a barrier to run-off water.

- This form of construction also affects adjacent crossflow ventilation and requires attention.

Timber is a hygroscopic material - that means it is capable of absorbing and expelling moisture and doing so it affects the nominal size of timber products and or its performance. There are many building products that are manufactured with timber fibre from structural framing, LVL's, plywoods particle board and flooring to name only a few. Therefore, it is imperative to ensure crossflow ventilation is complaint to BCA requirement. This is a must not only to protect your investment but also to provide an environment for healthy living.

Crossflow ventilation is a complex area and requires solid building knowledge, geographic location analysis, understanding of soil mechanics, relative humidity, products used and footprint design.

If you are unsure that your home or project is within compliance or require advice, please do not hesitate to call us.

Crossflow ventilation is a complex area and requires solid building knowledge, geographic location analysis, understanding of soil mechanics, relative humidity, products used and footprint design.

If you are unsure that your home or project is within compliance or require advice, please do not hesitate to call us.

View More Pages

Monticello Parquetry by Masterfloors

by MasterFloors

Timber Flooring Gallery - By Masterfloors

by MasterFloors

French Oak

by MasterFloors